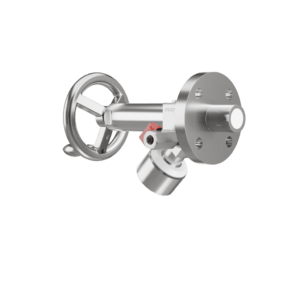

When it comes to maintaining accuracy and hygiene in industrial applications, a stainless steel sampling valve is an essential component. These valves are designed to extract representative samples from process lines or tanks, ensuring that quality control and analysis are performed with the highest precision. From the pharmaceutical and food and beverage industries to chemical and biotechnology sectors, stainless steel sampling valves play a critical role in enhancing operational efficiency and product quality.

What is a Stainless Steel Sampling Valve?

A stainless steel sampling valve is a device crafted from high-grade stainless steel, typically 304 or 316, specifically designed to draw samples of liquids, gases, or slurries. These valves are known for their durability, corrosion resistance, and hygienic properties, making them ideal for applications where cleanliness and accuracy are paramount.

Key Features of Stainless Steel Sampling Valves

- Corrosion Resistance: Constructed from premium stainless steel, these valves are highly resistant to corrosion and rust, ensuring long-lasting performance even in harsh environments.

- Hygienic Design: The smooth, polished surfaces of these valves prevent microbial growth and are easy to clean, meeting the strict sanitary standards of industries like pharmaceuticals and food processing.

- Precision Sampling: Stainless steel sampling valves allow for accurate and representative sampling, which is crucial for maintaining quality control and compliance with industry standards.

- Ease of Use: These valves often feature ergonomic handles and quick-release mechanisms, facilitating straightforward and efficient sample collection.

Types of Stainless Steel Sampling Valves

- Manual Sampling Valves: Operated by hand, these valves are ideal for applications where sampling is infrequent.

- Automated Sampling Valves: Integrated with automated systems, these valves enable remote operation and are perfect for high-frequency sampling needs.

- Aseptic Sampling Valves: Designed for sterile environments, these valves are commonly used in pharmaceutical and biotechnological processes to ensure contamination-free sampling.

Applications of Stainless Steel Sampling Valves

- Pharmaceutical Industry: Ensuring that drug formulations meet quality and safety standards through precise and sterile sampling.

- Food and Beverage Industry: Maintaining product quality and safety by taking representative samples of liquids and slurries.

- Chemical Industry: Monitoring chemical reactions and processes by extracting samples for precise analysis.

- Biotechnology: Ensuring the purity and consistency of biotechnological products through accurate and contamination-free sampling.

Checkes this page for more information about valves type.

Benefits of Using Stainless Steel Sampling Valves

- Enhanced Product Quality: By providing accurate and uncontaminated samples, these valves help maintain high product quality and integrity.

- Regulatory Compliance: Ensuring that your sampling process meets industry standards and regulatory requirements, thereby avoiding compliance issues.

- Cost-Efficiency: Durable and easy to clean, stainless steel sampling valves reduce maintenance costs and operational downtime.

- Safety: Designed to prevent leaks and contamination, these valves enhance the overall safety of your process, protecting both the product and the operators.

Conclusion

Stainless steel sampling valves are vital components in modern industrial processes, offering unmatched accuracy, hygiene, and durability. Incorporating these valves into your system ensures superior product quality, compliance with stringent regulations, and operational efficiency. Whether you’re in the pharmaceutical, food and beverage, chemical, or biotechnology sectors, stainless steel sampling valves provide the reliability and performance necessary to meet the highest standards.

Invest in stainless steel sampling valves today to elevate your precision, hygiene, and efficiency in industrial sampling processes.