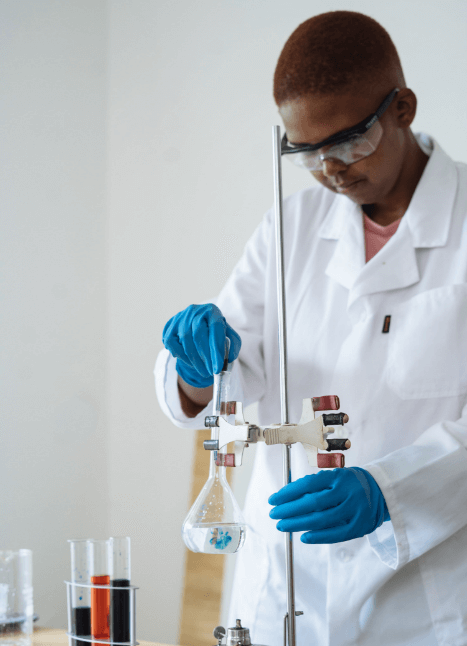

Engineered for Precision: The Power Behind Our Patented EPT® Technology

At FAMAT, we believe precise, safe sampling starts at the core of the valve. That’s why we developed EPT® – Expanding Piston Technology: an innovative mechanism that allows you to collect representative samples from pressurized systems without contamination, loss, or risk.

Unlike traditional diaphragm valves, EPT® expands directly into the product flow, retrieves a true sample, and retracts completely, leaving no product traps, no dead zones, and no cleaning headaches. Built for powder and liquid applications, our valves are fully CIP/SIP-compatible and ideal for pharma, chemical, and biotech environments.