Automated valves play a crucial role in enhancing the precision of industrial processes. By regulating the flow of fluids and gases with high accuracy, they enable companies to optimize their operations while ensuring product quality and safety. This article explores how automated valves contribute to precision across various industrial sectors.

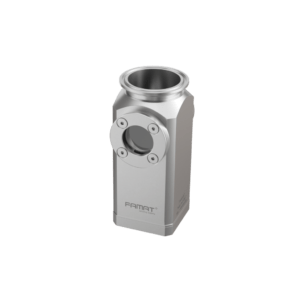

1. Functioning of Automated Valves

Automated valves are controlled by actuators that can be electric, pneumatic, or hydraulic. These actuators adjust the valve’s position based on signals received from a control system. This system may include sensors that measure variables such as pressure, flow rate, and temperature. When these values deviate from set points, the system sends a corrective signal to the valve to adjust its opening or closing.

Types of Automated Valves

– Ball Valves: Used for quick on/off applications.

– Butterfly Valves: Ideal for flow control in large diameter pipes.

– Globe Valves: Designed for throttling flow with high precision.

– Check Valves: Allow fluid to flow in one direction only, preventing backflow.

– Control Valves: Adjust flow rates based on external control signals.

2. Improved Precision in Processes

One of the primary benefits of automated valves is their ability to provide precise flow control. This is particularly important in applications where even small variations can significantly impact the final product’s quality.

Elimination of Human Error

Manual valves often rely on operators for their functioning, which can introduce human errors. Automated valves, on the other hand, operate based on measured data and control signals, thereby reducing the risk of mistakes. For example, in a chemical application, an automated valve can adjust the flow of a reagent according to process needs without human intervention.

Rapid Response to Changes

Automated valves can quickly respond to changes in process conditions. For instance, if pressure in a pipeline suddenly increases, an automated valve can close instantly to prevent overpressure. This ability to react swiftly helps maintain optimal conditions and prevent accidents.

3. Process Optimization

Automated valves also enable significant optimization of industrial processes. Their precision and speed help companies maximize operational efficiency.

Improvement in Product Quality

In the food and pharmaceutical industries, for example, precise control over ingredients is essential for ensuring product quality. Automated valves allow for accurate dosing of ingredients, thereby reducing the risk of variability in the final product.

Reduction in Production Downtime

Frequent shutdowns due to regulation issues can lead to substantial financial losses. Automated valves minimize these downtimes by ensuring smooth and consistent process control. This allows facilities to operate more efficiently and increase overall output.

4. Monitoring and Predictive Maintenance

Modern automated valve systems are often equipped with diagnostic technologies that monitor their performance in real-time. This capability allows for anticipating potential issues before they become critical.

Data Collection

The data collected by sensors can be used to analyze valve performance over time. This helps companies identify trends and plan maintenance before failures occur.

Proactive Maintenance

By using historical data on valve operation, companies can implement proactive maintenance programs that target the root causes of potential faults or failures. This not only reduces costs associated with unexpected repairs but also improves the overall lifespan of equipment.

5. Specific Applications Across Various Sectors

Automated valves are utilized across a range of industries, each with its own requirements for precision and control.

Chemical Industry

In the chemical industry, where precision is essential for ensuring safety and product integrity, automated valves regulate the flow of reactants with high accuracy. They also help maintain necessary conditions for various chemical reactions.

Water Treatment

In water treatment facilities, these valves control the precise dosing of chemicals needed for purification while minimizing waste.

Pharmaceutical Industry

The pharmaceutical industry also uses these valves to ensure strict control over fluids used in manufacturing, thereby ensuring compliance with stringent regulatory standards.

Conclusion

Automated valves play an essential role in improving precision and efficiency in industrial processes. By eliminating human error, allowing rapid responses to changes, and optimizing operations, they help ensure that finished products meet high standards required by various industries.

Investing in modern automated valve systems is therefore crucial for any business looking to enhance productivity while maintaining a high level of quality and safety. For more information about our products or if you need assistance choosing the right solution for your specific application, please do not hesitate to contact us!