Automation is revolutionizing every layer of pharmaceutical manufacturing, and sampling is no exception. Once seen as a manual, high-touch process vulnerable to human error and contamination, sampling is being redefined by Pharma 4.0. Automated solutions promise faster workflows, better data integrity, and lower risk, but only when executed with precision.

In this article, we’ll explore how automated sampling systems are reshaping quality control, how they align with regulatory shifts, and why forward-looking plants are upgrading now, not later.

Why Sampling Automation Is the Next Big Shift in Pharma

Traditional pharmaceutical sampling involves several manual steps, from tool sterilization to operator intervention to lab transport. Each step introduces variability and potential for human error. As drug formulations become more potent and regulatory scrutiny tightens, these gaps are no longer acceptable.

Automation minimizes these risks by enforcing repeatability. Automated systems ensure:

- Consistent timing of sample extraction

- Accurate volumes without manual pipetting

- Sealed transfer to closed containers or analytical systems

This reduces cross-contamination risk and strengthens your overall process validation strategy. For manufacturers handling high-potency APIs or aseptic workflows, automation isn’t just a performance upgrade, it’s becoming a necessity.

How Automation Enhances Contamination Control

One of the biggest advantages of automation is the elimination of direct human contact with the product or product path. Human intervention has long been the weakest link in maintaining a sterile or low-bioburden environment, even with stringent gowning and SOPs in place.

With automated sampling systems:

- Sampling events are triggered digitally, not manually

- Enclosed paths reduce airborne exposure and environmental variability

- Self-cleaning or CIP-compatible designs reduce the risk of microbial buildup between batches

For high-containment facilities or those operating under OEB 4/5 guidelines, automation helps eliminate subjective variables. Combined with robust mechanical systems like expanding piston valves, automated setups can offer both containment and cleanability, the two pillars of contamination control.

Regulatory Alignment: How Automation Supports Compliance

As regulatory bodies increase their focus on data integrity, traceability, and contamination prevention, automated sampling systems are becoming strategically important. Systems that automatically log sample time, batch number, and process conditions reduce the likelihood of missing or inaccurate records, a common finding during inspections.

Automation ensures that every sample is documented, traceable, and taken according to a pre-validated method. This kind of built-in compliance makes audits smoother and demonstrates a facility’s commitment to GMP, especially as regulators embrace digital maturity frameworks like the FDA’s CSA (Computer Software Assurance) and EMA’s Annex 11.

Real-Time Data & Integration with PAT

Automated sampling doesn’t just replace human labor, it enhances decision-making. When paired with Process Analytical Technology (PAT), samples can be analyzed in real-time or near real-time, feeding back into the control system to adjust parameters on the fly.

This feedback loop supports continuous manufacturing and reduces the need for end-product testing. In a landscape moving toward real-time release, automation offers a bridge between physical quality assurance and digital control strategies.

Challenges to Adoption: Cost, Legacy Systems, and Change Management

Despite the clear benefits, the shift to automation isn’t without barriers. Older facilities may struggle to retrofit sampling automation into existing process lines, especially when working with space constraints or non-modular equipment.

There’s also the issue of change management, staff need to be trained, protocols updated, and validation plans rewritten. However, many plants are now realizing that the long-term ROI of better compliance, reduced batch rejections, and faster QA cycles outweighs the upfront investment.

Modular Automation: A Scalable Path Forward

One of the most promising developments in automated sampling is modular system design. Instead of overhauling entire process lines, manufacturers can now integrate compact, standalone sampling modules that plug directly into existing equipment like reactors, dryers, or mixers.

These modules are particularly useful in multiproduct or contract manufacturing facilities where space is limited and flexibility is key. By starting small, teams can validate performance and scale up automation over time, minimizing disruption while gaining operational insight.

Improving Operator Safety Through Remote Sampling

Automated systems also address one of the biggest risks in pharmaceutical manufacturing: operator exposure. Manual sampling often requires opening process equipment, increasing the likelihood of exposure to hazardous substances, especially in HPAPI environments.

Remote-controlled or fully enclosed sampling units allow samples to be taken without direct human contact, reducing not only safety risks but also the need for extensive PPE and containment infrastructure. This aligns with the broader industry shift toward low-touch, safety-first design.

The Role of EPT® in Enabling Sampling Automation

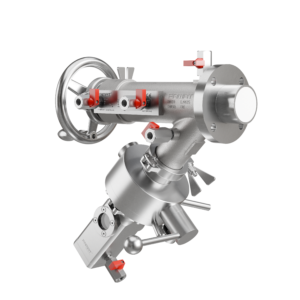

Expanding Piston Technology (EPT®) plays a foundational role in making sampling automation both effective and hygienic. Unlike traditional valves that rely on static seals, EPT® uses dynamic expansion to create a full-bore seal, eliminating dead zones and reducing the need for manual cleaning or intervention.

This makes EPT®-based sampling valves highly compatible with automated systems, especially when repeatable, contamination-free sampling is required. Their reliability and CIP/SIP compatibility mean fewer errors, faster cycles, and cleaner integrations with automated process lines.

Conclusion

Automation is not just a buzzword, it’s a practical shift redefining how pharmaceutical sampling is done. From reducing human error and improving traceability to enhancing safety in high-risk environments, the benefits are clear. As systems like EPT® make integration smoother and more reliable, the barriers to adopting automation are falling away.

For pharmaceutical manufacturers aiming to meet rising regulatory expectations while staying agile and efficient, automated sampling isn’t a luxury. It’s the next logical step. And as technology matures, it will become not just viable, but expected.