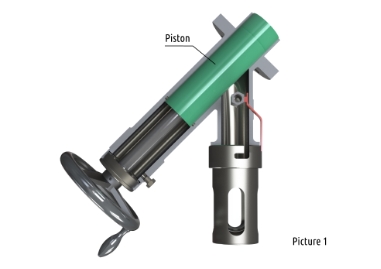

Almost all FAMAT valves are based on our patented Expanding Piston Technology EPT®.

The patented system inside this piston allows the ptfe external coat to expand and insure a perfect tightness from vacuum up to full rating pressure 10 bar (145 psi).

The advantage of having an expandable piston inside the valve is to eliminate the need for O-rings that can be damaged during valve operation, and consequently generate contamination (dust) for production.

Another big advantage of our design is that in closed position, the piston is flush with the connection point, leaving no dead space.

CLOSED POSITION The piston is flush with the reactor or dryer, leaving no dead space. A perfect seal is formed directly by the piston against the body of the valve.

SAMPLING PROCEDURE Turn the handwheel counter clockwise to lower the piston to its open position. While the product flows down into the sampling bottle, the operator can check the desired quantity of the product through the sight glass.

Turn the handwheel clockwise to bring back the piston in its closed position. A firm final turn of the handwheel will give reliable sealing and no dead space. Equalise the pressure (or vacuum) in the chamber by opening the purge/venting valve. Remove the sampling bottle on its quick coupling connection.

CH – 1933 Sembrancher

Switzerland

tel : +41 27 552 11 11

fax : +41 27 552 11 10

info@famat-sampling.com

BIAR GROUP

the sampling expert

Biar group is made up of swiss companies, recognized experts in sampling systems. due to its solutions for liquid, gaz and solids, Biar group responds to the needs of its customers request in sampling domain with a global reliable and responsive offer.

copyright © 2024 – famat sampling sa

all rights reserved