Handling Highly Potent Active Pharmaceutical Ingredients (HPAPIs) demands uncompromising protection for both operators and product. Traditional containment systems often rely on bulky isolators or complex transfer technologies—driving up CAPEX, maintenance costs, and cleaning complexity.

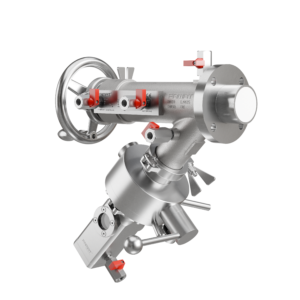

FAMAT’s high-containment sampling solution, featuring a split butterfly valve (SBV) interface, delivers up to OEB5-level containment within a compact, modular design.

Engineered for seamless integration on reactors, dryers, and mixers, it ensures aseptic, contamination-free sampling even in the most confined or sensitive production environments.

Key Features & Advantages

-

✅ OEB4/5-compliant containment for HPAPI and cytotoxic compounds

-

✅ Operator-safe sampling through a fully sealed and automated transfer interface

-

✅ Compact footprint, easily adaptable to existing process lines and gloveboxes

-

✅ Reduced cleaning and validation workload thanks to smooth, crevice-free internal design

-

✅ Robust stainless-steel construction suitable for CIP/SIP and steam sterilization

-

✅ Modular and scalable concept, compatible with various SBV or containment systems

By combining precision engineering and process safety, FAMAT simplifies HPAPI sampling and containment — delivering reliability without the complexity of full isolator systems.

💡 Looking to optimize your HPAPI containment strategy?

Let’s design your next-generation sampling solution together.