In the pharmaceutical and biotechnology industries, precision, cleanliness, and traceability are non-negotiable. From raw material verification to final product validation, every stage of the process requires accurate data collection and strict quality assurance. This is where FAMAT Sampling solutions stand out. Designed to provide reliable, hygienic, and safe sampling systems, FAMAT’s technology ensures that every sample taken is representative of the process, uncontaminated, and compliant with the highest regulatory standards. For manufacturers seeking to improve control, minimize risk, and guarantee product integrity, FAMAT has become a trusted partner worldwide.

Understanding the role of Sampling in Pharmaceutical and Biotech processes

Sampling plays a critical role in ensuring that pharmaceutical and biotech products meet stringent quality and safety requirements. Before any batch is approved, samples are collected from different stages of production, such as reactors, tanks, or pipelines to assess purity, composition, and compliance with Good Manufacturing Practices (GMP). This process is essential not only for quality control but also for maintaining process consistency, detecting deviations early, and preventing costly product losses.

FAMAT Sampling solutions are specifically engineered to meet these needs. They allow operators to collect samples safely without compromising sterility or introducing contamination into the process line. Unlike traditional sampling methods, which often expose materials to air or human contact, FAMAT systems ensure a closed, aseptic environment that aligns with the most demanding industry standards, such as FDA and EMA regulations.

Key Features and Benefits of FAMAT Sampling Systems

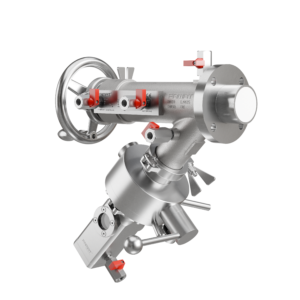

FAMAT’s sampling technology brings together mechanical precision, hygienic design, and operational safety. Although Famat’s valves are not officially EHEDG certified, they are successfully used in many critical pharmaceutical and chemical applications where hygiene and product integrity are essential.

FAMAT sampling valve is meticulously designed to comply with hygienic practices, ensuring the highest level of process integrity.

Some of the main advantages of FAMAT Sampling systems include:

- Aseptic and sterile operation: The design prevents external contamination, allowing samples to be taken without exposing the product to the environment.

- Modular and customizable configurations: Each system can be tailored to the specific requirements of the process, whether manual or automated sampling is needed.

- Easy cleaning and maintenance: The valves are constructed from high-quality stainless steel with polished surfaces, facilitating clean-in-place (CIP) and sterilize-in-place (SIP) procedures.

- Safety for operators: Built-in protection mechanisms and controlled flow paths minimize exposure to hazardous substances.

These benefits result in higher product quality, process efficiency, and regulatory compliance, making FAMAT equipment a strategic investment for pharmaceutical and biotech manufacturers aiming to optimize their operations.

Applications of FAMAT Sampling in the Pharmaceutical Industry

In the pharmaceutical industry, every detail matters.Sampling must be performed with absolute precision to ensure the integrity of the final product.

FAMAT Sampling systems are used in a wide range of applications, including the sampling of solid formulations, whether free-flowing, cohesive, or semi-solid, as well as for the verification of active ingredients.

During the production of pharmaceutical intermediates, operators must collect samples to verify product conformity at various stages of the process. FAMAT valves enable these samples to be taken under closed conditions, ensuring both the integrity of the sample and the absence of cross-contamination.

In processes requiring aseptic or contained conditions — such as the formulation of vaccines or the manufacture of sensitive active ingredients — FAMAT sampling systems can be configured in a closed mode, providing a complete separation between the process and the environment.

This allows representative sampling without disturbing the ongoing process, while maintaining the highest standards of hygiene and safety.

Thanks to their adaptable design, FAMAT solutions are also suitable for solid, granular, crystalline, or pasty materials, whether dry, humid, or slightly cohesive.

This flexibility ensures that every product type, regardless of its physical characteristics, can be sampled in a safe, reproducible, and precise manner.

Applications of FAMAT Sampling in Biotechnology

In biotechnology, sampling plays a decisive role in process monitoring and product consistency. Certain biotech processes involve the handling of solid, granular, or semi-solid materials, such as dry powders, lyophilized media, or moisture-sensitive intermediates.

FAMAT Sampling systems are designed to meet these specific needs by enabling representative sampling of such materials while maintaining process integrity and cleanliness.

FAMAT valves can be sterilized or cleaned in place (CIP/SIP) according to process requirements, ensuring continuous protection between each sampling cycle.

This approach guarantees high reproducibility and full traceability, which are essential in the development and production of biopharmaceuticals, complex nutrients, or biological additives in solid form.

Thanks to their mechanical robustness and precise engineering, FAMAT technologies are used in research laboratories, pilot plants, and large-scale production facilities alike.They contribute to improved process efficiency, operator safety, and analytical reliability, while minimizing the risk of cross-contamination.

Material and Design Excellence

Every detail of FAMAT equipment is engineered to ensure durable performance and impeccable hygiene. The sampling valves are manufactured from 316L stainless steel or other corrosion-resistant alloys, capable of withstanding aggressive cleaning agents and sterilization cycles.

Their polished internal surfaces prevent product build-up and reduce the risk of particulate or microbial contamination, while the valve seals are made from FDA-approved elastomers.

Beyond material selection, FAMAT Sampling systems are designed for ergonomic, safe, and long-lasting operation.Their intuitive controls and smooth surfaces make handling easy, even in demanding production environments.

Each valve is engineered for minimal maintenance and maximum uptime, delivering consistent performance across thousands of sampling cycles.

This proven robustness and precision make FAMAT a preferred solution for pharmaceutical and biotechnology applications requiring cleanliness, reliability, and reproducibility.

Compliance and Certification

Regulatory compliance is a cornerstone of the pharmaceutical and biotechnology industries, and FAMAT ensures that its equipment meets or exceeds all applicable standards. Each sampling system is designed and manufactured in accordance with GMP, FDA, and USP Class VI requirements, ensuring that all product-contact materials are biocompatible, safe, and fully traceable.

FAMAT’s engineering and quality control processes are ISO 9001 certified, guaranteeing rigorous inspection and documentation at every stage of design and production. Comprehensive traceability and technical documentation are integral to each sampling system, enabling seamless integration into customers’ quality management systems and regulatory frameworks.

By choosing FAMAT Sampling solutions, manufacturers not only optimize process performance and product reliability, but also reinforce their ability to demonstrate compliance during audits and regulatory inspections.

Why is FAMAT the Trusted Partner for Pharmaceutical and Biotech Sampling ?

What sets FAMAT apart is its commitment to precision, innovation, and customer collaboration. Rather than offering one-size-fits-all products, FAMAT works closely with clients to design systems that fit their specific process conditions and safety requirements. The company’s deep expertise in hygienic design, combined with its continuous innovation efforts, ensures that its solutions remain at the forefront of industry technology.

FAMAT’s global presence and technical support network provide peace of mind for operators and engineers alike. Whether for a small-scale biotech laboratory or a large pharmaceutical production site, FAMAT delivers the same level of quality, reliability, and after-sales service. This combination of engineering excellence and customer focus makes FAMAT Sampling a reference brand trusted by industry leaders worldwide.

Conclusion

In the world of pharmaceuticals and biotechnology, precision and sterility are the foundations of quality and safety.

FAMAT Sampling solutions embody these principles through advanced engineering, hygienic design, and an unwavering commitment to compliance. Their systems enable manufacturers to obtain representative, contamination-free samples, ensuring that every batch meets the highest regulatory and quality standards.

As the industry continues to evolve toward automation and data-driven process control, FAMAT remains at the forefront, delivering sampling technologies that combine innovation, reliability, and proven performance For any company seeking to enhance process monitoring and guarantee product integrity, partnering with FAMAT is more than a choice of equipment ; it is a commitment to excellence.