In modern industrial processes, sampling valves play a critical role in maintaining quality and ensuring operational efficiency. These specialized components enable precise sample collection, helping industries uphold safety standards and regulatory compliance. As demand for accurate monitoring continues to rise, the global sampling valve market is experiencing substantial growth. For businesses looking to stay ahead, understanding their applications and market potential is key to unlocking new opportunities.

What are Sampling Valves and How Do They Work?

Understanding the Basics of Sampling Valves

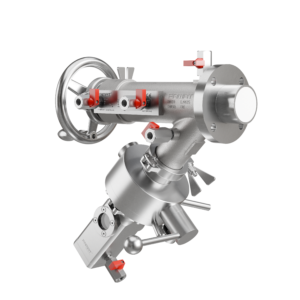

Sampling valves are a type of valve specifically designed to extract samples from pipelines or tanks containing liquids, gases, or slurries. These valves are used to obtain samples for analysis without disrupting the ongoing process. By allowing an efficient sampling process, they play a crucial role in maintaining quality control within various industries. Unlike gate valves, butterfly valves, or ball valves, sampling valves are engineered to minimize contamination risk, ensuring the integrity of the sample collected.

How Are Sampling Valves Used in Various Industries?

Sampling valves are utilized across numerous industries due to their versatility and reliability. In the food and beverage sector, they ensure that products meet safety and quality standards. In the chemical industry, these valves play a crucial role in monitoring reactions and ensuring product consistency. Similarly, in water and wastewater treatment, sampling valves are essential for testing and ensuring compliance with environmental regulations. The increasing demand for high-quality and consistent products has driven the adoption of sampling valves across various sectors.

Key Features of Aseptic Sampling Valves

Aseptic sampling valves are specifically designed to prevent contamination, making them indispensable in industries where sterile conditions are paramount, such as pharmaceuticals and biotechnology. These valves are constructed using materials that withstand sterilization processes and are capable of ensuring the purity of the samples collected. Their unique design allows for easy cleaning and maintenance, enhancing their reliability and effectiveness in critical applications.

What Market Trends are Influencing the Sampling Valve Market?

Current Trends in the Sampling Valve Market

The global sampling valve market is experiencing a surge in demand, driven by the need for improved quality control and regulatory compliance. Market trends indicate a shift towards valves designed with advanced materials and smart technologies that enhance their functionality and efficiency. Additionally, the rising focus on sustainability and environmental impact has propelled the development of eco-friendly sampling solutions.

Impact of Emerging Markets on Sampling Valve Demand

Emerging markets are playing a significant role in the increasing demand for sampling valves. As these markets expand, there is a growing need for industries to adhere to international quality standards, thereby boosting the demand for reliable sampling solutions. Market research suggests that the sampling valve market is expected to witness significant growth in regions where industrialization and urbanization are rapidly advancing.

Future Projections and Market Growth

The sampling valve market is projected to reach USD figures that reflect its anticipated growth trajectory. With innovations in valve technology and the expansion of industrial sectors, growth opportunities abound. The market is expected to continue evolving, with companies investing in research and development to produce valves that meet the changing needs of industries worldwide.

Which Sectors Benefit Most from Sampling Valve Applications?

Role of Sampling Valves in the Food and Beverage Industry

In the food and beverage sector, Famat sampling play a crucial role in ensuring that products meet stringent safety and quality standards. These valves are used to extract samples for microbial and chemical analysis, helping manufacturers maintain product consistency and comply with regulatory requirements. The market share of sampling valves in this sector is substantial, reflecting their importance in quality control processes.

Importance of Sampling Valves in Water and Wastewater Treatment

Sampling valves are indispensable in water and wastewater treatment facilities, where they are used to monitor water quality and ensure compliance with environmental regulations. These valves facilitate the collection of samples for testing, enabling operators to detect contaminants and adjust treatment processes accordingly. The reliability of these valves in harsh environments is crucial for maintaining the integrity of water treatment systems.

Application of Sampling Valves in the Chemical Industry

The chemical industry relies heavily on sampling valves to monitor and control chemical reactions and processes. These valves are designed to withstand the aggressive conditions often present in chemical manufacturing, ensuring that samples are collected safely and accurately. The role of sampling valves in this sector is vital for ensuring process efficiency and product quality.

How Do Sampling Valves Enhance Quality Control and Reliability?

Ensuring Quality Control in Industrial Applications

Sampling valves are essential tools for ensuring quality control in industrial applications. By facilitating the accurate and uncontaminated collection of samples, these valves enable manufacturers to conduct thorough analyses and maintain high standards of product quality. This capability is crucial for industries aiming to meet both customer expectations and regulatory requirements.

Reliability of Sampling Valves in Harsh Environments

The reliability of sampling valves in harsh environments is a key factor in their widespread adoption across various sectors. These valves are engineered to perform consistently under extreme conditions, such as high temperatures, pressures, and corrosive environments. This reliability ensures that critical processes can continue uninterrupted, thereby safeguarding operational efficiency and product quality.

Benefits of Using High-Quality Sampling Valves

Using high-quality sampling valves offers numerous benefits, including enhanced accuracy, durability, and ease of maintenance. These valves are designed to reduce downtime and improve operational efficiency, ultimately contributing to a company’s bottom line. Investing in quality valves also minimizes the risk of contamination and ensures compliance with industry standards, providing peace of mind to operators and stakeholders alike.

How is the Sampling Valve Market Size Determined?

Factors Influencing Market Size and Share

Several factors influence the market size and share of the sampling valve market. These include technological advancements, regulatory requirements, and the increasing demand for efficient sampling solutions across various industries. Additionally, the expansion of industrial sectors and the need for enhanced quality control measures are driving the growth of the market.

Significance of Market Size in Predicting Industry Trends

The market size of the sampling valve industry is a critical indicator of industry trends and growth potential. A larger market size often reflects increased adoption and innovation within the sector, signaling opportunities for investment and development. Understanding market size helps stakeholders make informed decisions about resource allocation and strategic planning.

Regional Variations in the Sampling Valve Market

Regional variations play a significant role in shaping the sampling valve market. Factors such as economic development, industrialization, and regulatory frameworks differ across regions, impacting the demand and adoption of sampling valves. Market research highlights that while developed regions continue to dominate the market, emerging markets are exhibiting rapid growth, offering new opportunities for expansion and investment.

Conclusion

As industries continue to prioritize quality control, safety, and regulatory compliance, the role of sampling valves remains indispensable. These specialized valves are integral to maintaining product integrity across sectors such as food and beverage, pharmaceuticals, chemicals, and water treatment. With advancements in valve technology and growing industrial demands, the global sampling valve market is poised for significant expansion. Businesses that invest in high-quality sampling solutions and stay ahead of market trends will be well-positioned to capitalize on emerging opportunities. Moving forward, innovation, sustainability, and adaptability will drive the future of the sampling valve industry, ensuring its continued evolution in an increasingly quality-conscious world.